Technical designation

1.4301, X5CrNi 18 10, AISI 304L

1.4401, X2CrNi 17 13, AISI 316L

Available thicknesses

- 0.5 mm

- 0.8 mm

- 1.0 mm

- 1.2 mm

- 1.5 mm

- 2.0 mm

- 2.5 mm

- 3.0 mm

- 4.0 mm

- 5.0 mm

- 6.0 mm

- 8.0 mm

Alloys

Stainless Steel 304

Stainless Steel 316

Finishes

Unfinished (2B), Vibrated, SandBlasted, Brushed (1S) and Shiny (BA).

Main features

The 304 variant have a good resistance against oxidation. The 316 alloy is special for high corrosion or marine environments.

Ease of forming using tools, both alloys are good for welding operations.

This material is strong, hard and is not attracted by magnets.

Aesthetic finishes available for this material.

Surface finish and thickness tolerance according to EN 10131.

Appearance of Stainless Steel Finishes

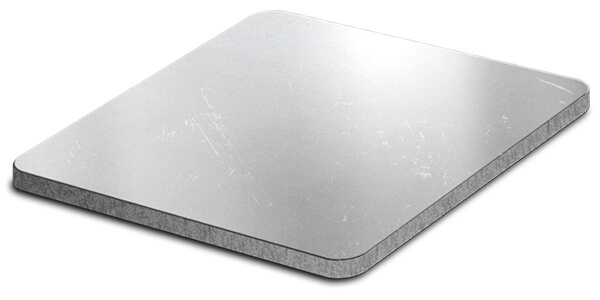

Stainless Steel

Unfinished factory-source finish. Front side can contain smooth scratches. Back Side can contain burrs and scratches from cutting process. Back-Side deburring process available in part configurator.

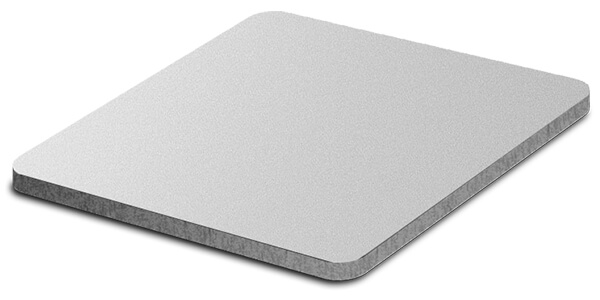

Stainless Steel -

Vibrated

Stainless Steel - SandBlasted

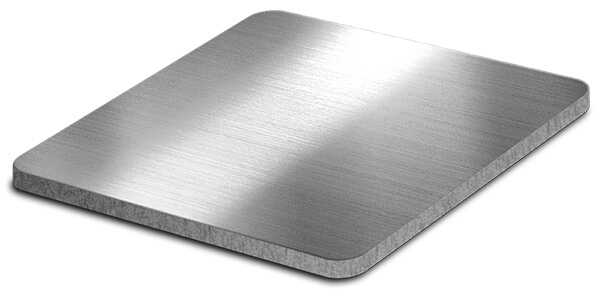

Stainless Steel - Premium Brushed

Manually brushed finish with a high end aesthetic result. Finish applied in the face shown in your files. Horizontal brushed alignment. *

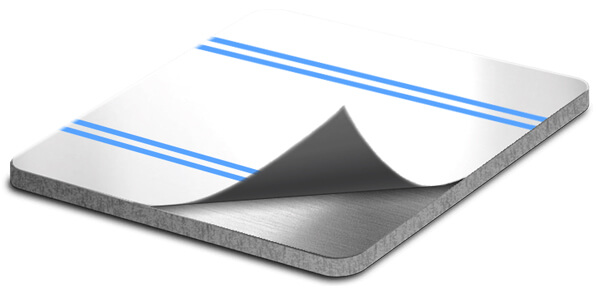

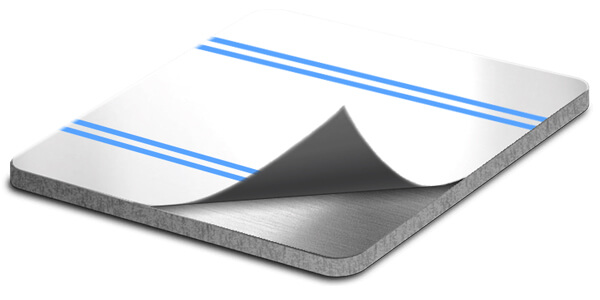

Stainless Steel - Brushed SB (with film protection)

Brushed Stainless Steel SB comes with a factory PVC film protection. Finish applied in the face shown in your files. Horizontal brushed alignment. *

Stainless Steel - Premium Shiny

Manually shiny finish with a high end aesthetic result. Finish applied in the face shown in your files. *

Stainless Steel - Shiny BA (with film protection)

Shiny Stainless Steel BA comes with a factory PVC film protection. Finish applied in the face shown in your files. *

Brushed and Shiny Finish Considerations *

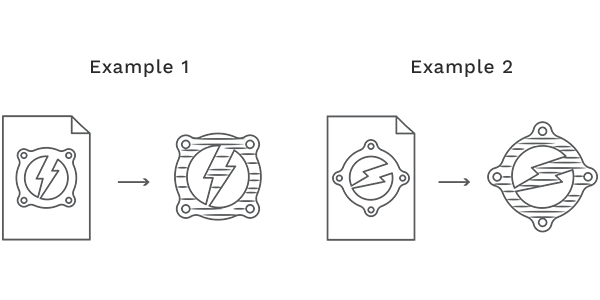

The Brushed and Shiny Finish will always be present on the front face of your file.

The brushing alignment will always be horizontal, according to the position of your documents.

In Premium finishes, select the extra option to get the finish applied in both faces.

Stainless Steel Laser Cutting Service

– Resistant to everything. Irresistible to the eyes.

We have 304 alloy, perfect for most applications, and 316, ideal for high corrosive or marine environments.

Stainless steel is an easily weldable material, ready to be cold formed, rigid, very durable, clean and is not attracted by magnets.

In the vibrated variant we polish both faces with abrasive discs, offering an industrial non-directional homogeneous finish.

About the sandblasted finish, we operate at low pressure with glass microspheres to sand without affecting the original shape of your part, leaving the surface clean and free of imperfections.

For a more aesthetic result, we recommend the Brushed or Shiny finish. This finish is present on the front face of your file. If you select the extra aesthetic finish, your part will be polished after being cut on both sides.

Stainless steel has a wide range of applications, including pieces for: home appliances, vehicles, assemblies for outdoors, general industrial equipment, chemical and food industrial machinery, jewelry, signage, decorative letters, DIY projects and all kinds of applications where solid, resistant parts with an optimal natural protection against environmental oxidation and corrosion are needed.

Enjoy our stainless steel parts and stainless steel sheets cut to size.

Order Your Stainless Steel Parts Online Now

- Instant price

- Online configurator

- From 1 to 10,000 parts

- Your order ready in 72h

- Invoice instantly via email

- Optional user or company account

Instant price and online configurator. Your parts in 72h.