The automotive industry, with its demanding quality standards, aims to ensure that the end customer, the vehicle buyer, enjoys a product where everything fits perfectly.

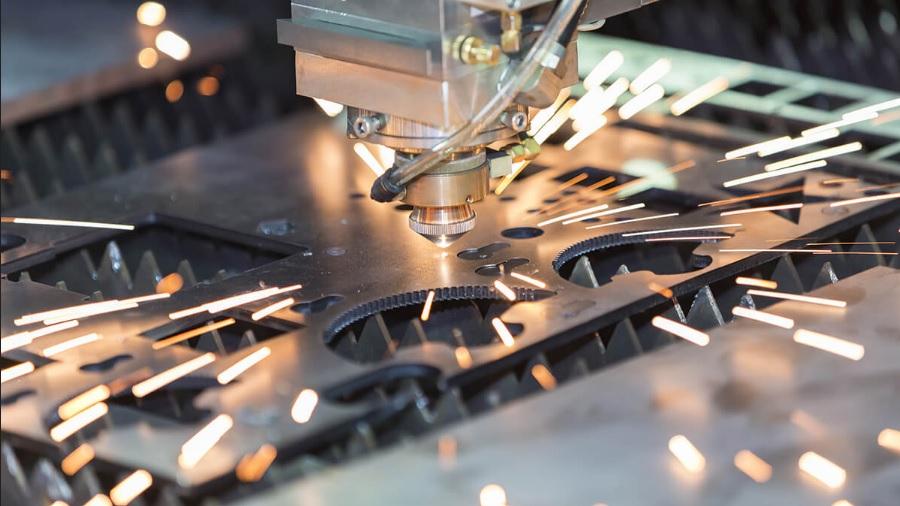

Traditional processes can achieve good or very good tolerance and fit values, but this is not always enough. This is where laser cutting technology comes in to achieve the extra quality desired by car manufacturers (OEMs) and so highly valued by the buyers of their products.

How is laser cutting used in the automotive industry?

Laser cutting, either fiber or CO2, uses an intense, coherent beam of monochromatic light created by a stimulated emission of electromagnetic radiation. One of the advantages of these light beams is that they can achieve the required cut with very tight tolerances and, in addition, with very low process variability.

There are industrial processes that need to be completed with subsequent processes to achieve the required dimensional quality. Some stamping technologies are among those processes that are completed with the assistance of a laser cutting machine.

However, those technologies are continuously improved to avoid the need for subsequent reprocessing due to its impact on the final cost of the part. In other cases, such as some parts made from metal tubes, complex geometries are generated that can only be processed on laser cutting machines.

It can be said that laser cutting technology is an ideal complement to those part manufacturing technologies that cannot meet the requirements of the automotive industry on their own.

And not only that.

Laser cutting and art

In artistic creation there is no limit but the imagination. In the artist’s brain, everything fits together perfectly and the designs flow smoothly – there is no need for tolerances, adjustments, rework or revisions. And the time comes to materialize the creations. In the case of works in metal, such as steel, aluminum, brass, copper or others, the artist

may feel intense frustration if the embodiment of his ideas on the material support does not achieve the imagined dimensional quality.

The laser cutting in two dimensions achieves, as can be seen in the images that accompany this text, to accompany the artists breaking all barriers that were limiting their creative capacity.

The laser, hand in hand with LASERBOOST, with the industry and with art.

Images:

- https://www.market-prospects.com/

- https://unsplash.com/photos/Spq4fuFM4Kw